I wanted to work more directly with clay and fire, exposing the clay’s character through a more active response to soda vapor.

-Gail Nichols

|

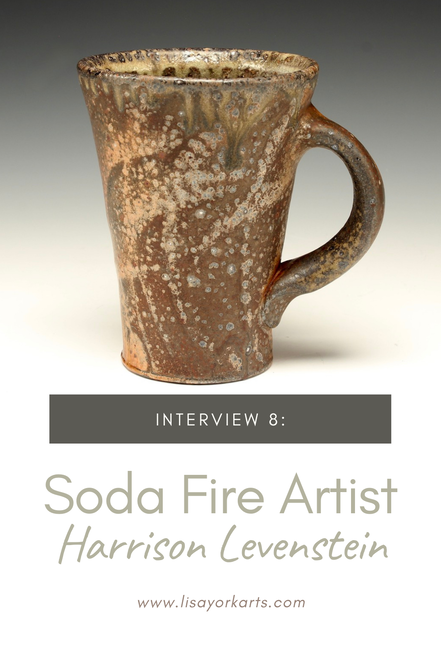

Soda-firing is the process in which sodium oxide (soda) is introduced into the hot kiln. Once inside, it will vaporize and interact with the red hot surfaces of the work leaving beautiful flashes of color and glaze. As the sodium vapor flows through and around the glowing hot pottery, it binds to the silica molecules on their surfaces to create a glassy glaze which tapers into gradients of color called flashing. Since the soda fuses to the surfaces of the work in this way, it blurs the line between pot and glaze/surface; they become one. The introduction of this soda vapor into the kiln’s atmosphere which then has a dramatic effect on the pots makes this process, much like wood-firing, an atmospheric firing process.

The soda is introduced in the form of Sodium Carbonate (soda ash) and/or Sodium Bicarbonate (Baking Soda) using a variety of methods depending on the intention of the artist. When I soda-fire, I mix soda ash into solution with hot water, and spray it into the kiln using a pressurized weed sprayer. Using protective gear, I spray directly into the kiln through the burner ports (pictured above) in order to allow the vapor to flow through the kiln following the natural path of the flame produced by the burners. My intention is to collaborate with the flame in the finishing of my pots, and I've carefully curated set of techniques that help me achieve that end. Gail Nichols sums up my fascination with atmospheric firing processes in this quote from her book, Soda, Clay and Fire, “I wanted to work more directly with clay and fire, exposing the clay’s character through a more active response to soda vapor.” If you are curious about the nitty gritty of my process, please check out these blog posts that I have written detailing the specs of my firings. |

|